Handloom

Our handloom journey has been a five-year process for us, learning from many mistakes along the way. Initially we worked with more traditional elements of the design process before we started designing our own jamdani designs. As a qualified pattern maker and designer this process has taught me valuable lessons in accepting the small flaws that come with the handmade process. To see perfection in small imperfections.

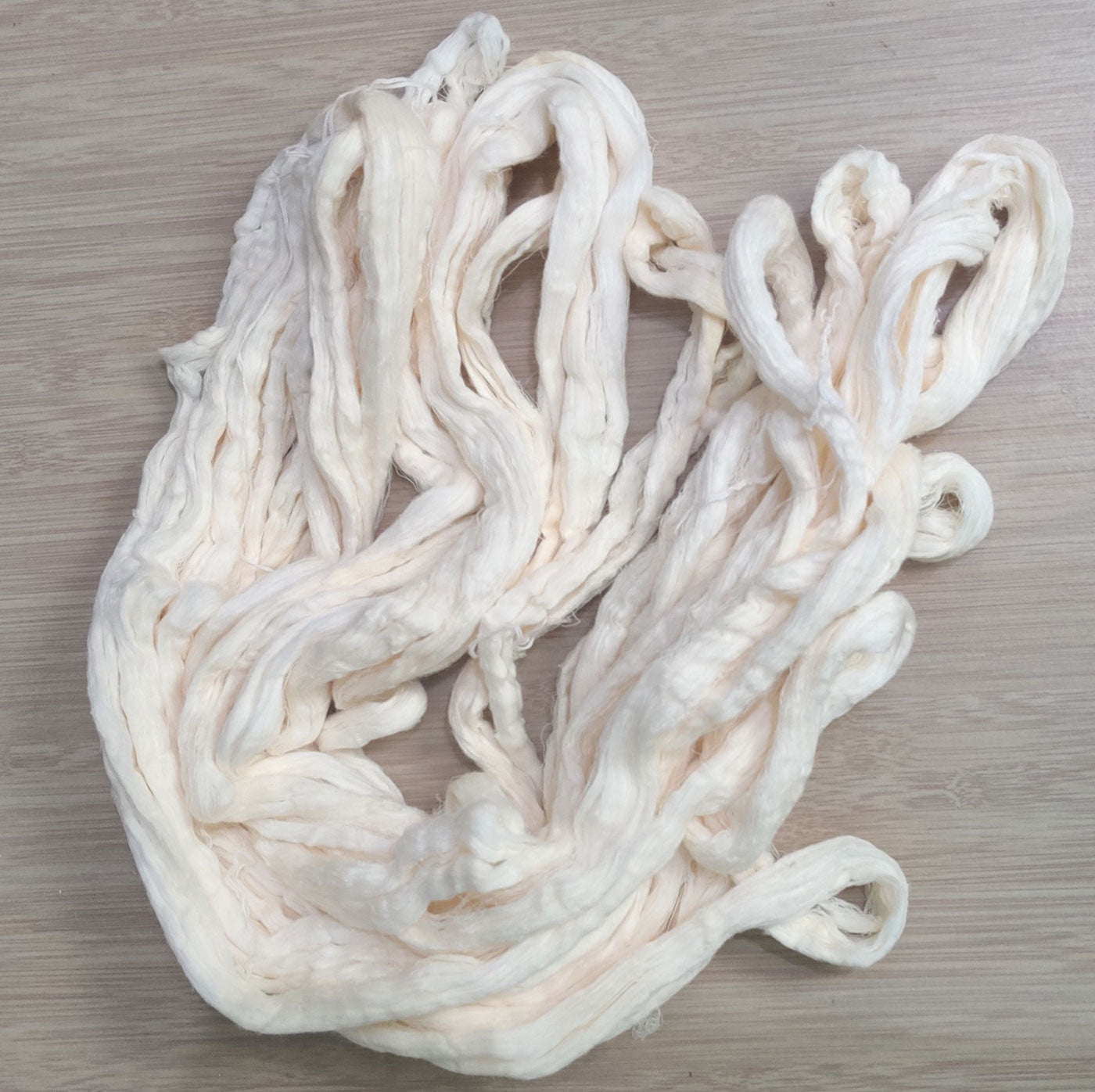

All our cotton yarn we use is hand spun. We generally use a 150-count khadi, which is a very fine yarn. This creates a beautifully soft and breathable fabric.

Handloom

Margaux Dress Handloom - Match Stick

Sale priceR2,900.00

Regular priceR3,600.00

Everly Dress Handloom - Rainbow Stripe

Sale priceR2,900.00

Regular priceR3,600.00